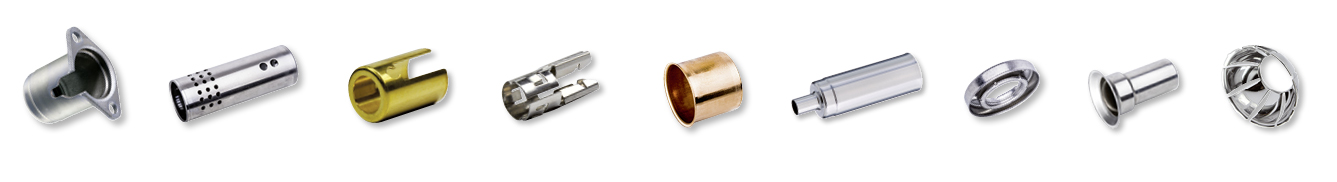

HIGHLY PRECISE DEEP-DRAWN PARTS

High-precision deep-drawn parts made of stainless steel, steel and non-ferrous metals are produced in modern production facilities. Our production focuses on thin-walled and mostly rotationally symmetrical hollow bodies with wall thicknesses of 0.15 to 2.3 mm. This requires the tightest tolerances in terms of dimensions, shape and position.

We also meet the high demands on the surface quality of the

components. In addition, the component cleanliness plays an increasingly important role. If necessary, the surfaces of the components are mechanically or galvanically post-processed. Every year, our company processes about 1,200 t of stainless steel, 2,900 t of steel and 80 t of non-ferrous metals.

The know-how of our employees, combined with state-of-the-art production facilities, enables us to produce the most complicated geometries, which in extreme cases require more than 20 forming steps, while maintaining the required precision and quality.

We deliver our products to many destinations worldwide. These become components of assemblies in almost all areas of the automotive industry and many different industries.

MATERIALS

The deep-drawn parts of our production are made of steel, stainless steel and various non-ferrous alloys. Each material has specific properties that are considered in the forming process. Non-binding consulting services in advance prepare drawing technology solutions that customers can use to develop their products.