MARKET SEGMENTS

Automotive

e.g. housing for airbags, ABS, lambda probes, sensors, fuel control, guide tubes, locking systems, heating cartridges and trim panels. More than 60% of our production goes into this market segment.

Sanitary

e.g. components for shower hoses, shower fittings and water taps

Domestic appliances

e.g. temperature sensors for coffee and dishwasher machines, bearing housings for washing machines, components for gas meters

Control and measuring technology

e.g. housings and guide sleeves for switching and proportional solenoids, sleeves for sensors

E-mobility

e.g. deep-drawn components, such as connectors for hybrid cars and electric vehicles

Electrical engineering

e.g. parts for lighting technology, as well as components for floodlighting systems

Locking technology

e.g. sleeves for lock cylinders as well as cover and ornamental caps

Machine and plant construction

e.g. components for the control of pneumatic and hydraulic systems

REFERENCES

REFERENCE PARTS

Sensor sleeve

Sleeves produced from various stainless qualities on transfer presses, then annealed to allow further transformations. These sleeves often have extreme diameter to length ratios.

Sleeve

Sleeves made of 1.4301 using progressive dies with multiple cavities. Sleeves are degreased after the drawing process and polished to meet the visual requirements.

Tips for writing utensils

Thin-walled conical and bulbous sleeves made of stainless material on transfer press.

Airbag sleeve

made of pre-galvanised DC04 (galvan). The 24 side holes are produced on a transfer press and tested to 100%.

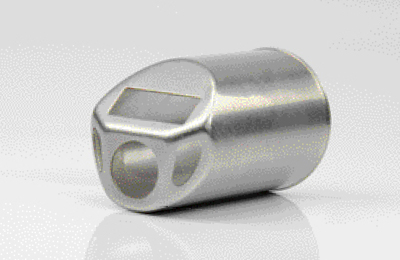

Cap for lock cylinder

made of 1.4301 or CuZn28 with lateral notching on a transfer press. Part is turned in the process.

Burner mounting clamp

manufactured on progressive dies as a punched bent component with 2 cavities of H2D 44RRSt3Lg.

Beam splitter

made of CuZn36 on progressive dies with several cavities including the side windows, also nickel-plated as required.

Universal ball joint

made of 1.4571 (increased acid and industrial water resistance) on a punching press in the progressive die.

Magnet housing

manufactured on transfer press from DC 04 with different wall thicknesses and several fitting seats. The fine thread was subsequently produced by machining.

Clamping sleeve

Non-rotationally symmetric sleeve made of Cu Zn 30 on a transfer tool. Then silvered to increase its conductivity.